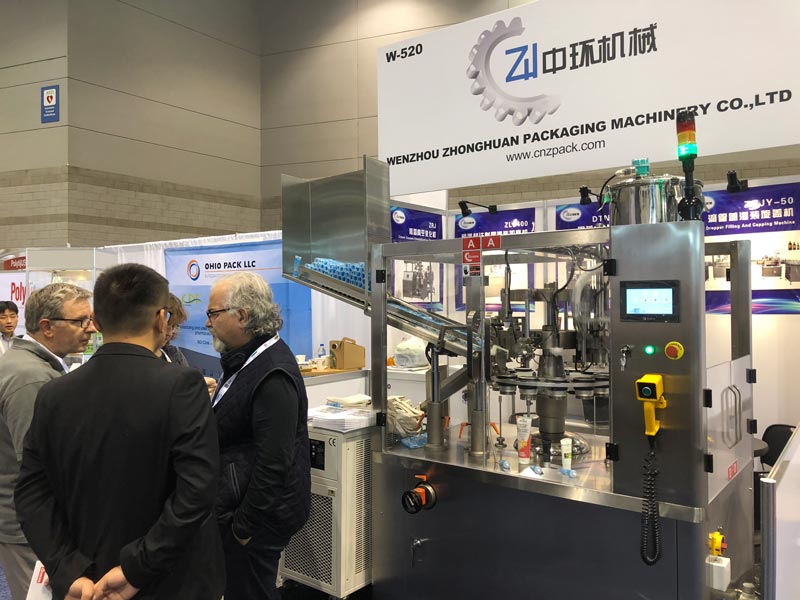

The automatic filling machine equipment has been independently developed and improved to meet the needs of some large companies. It is mainly used for the production of large companies, effectively improving production efficiency and marketing level.

To meet your needs, this machine is mainly used for bottle filling in the liquid, paste, sauce, lotion, and cream material industries.

Nail polish filling and capping machine Nail polish filling and capping machine is manufactured with international advanced technology, and imported parts, electrical and pneumatic components are selected, drip-proof, drip-proof drawing filling partition, and anti-foam product filling The lifting system, positioning system and liquid level control system ensure that the bottle mouth is in place, and adopts multiple heads and multiple pumps to control separately and adjust the speed of a single inverter, which overcomes uneven flow distribution, is easy to adjust, intuitive and accurate, and is used Power filling reduces production costs, improves filling efficiency, and uses electrical and gas main components. High-quality components can ensure the reliability, accuracy, stability and durability of the system.

The automatic filling machine realizes quantitative filling by controlling the plunger pump by the servo motor. The filling volume of the filling machine can be arbitrarily set within the rated range. The inch touch screen operation display screen, full Chinese man-machine interface, including help information, is intuitive and easy Understand, very few built-in adjustable parameters, fool-like operation design, the automatic filling machine adopts a lifting filling head device, deep into the bottle filling without bubbles, equipped with a color touch screen, the touch screen contains operation, monitoring, operating instructions, etc. A variety of functions.

The automatic filling machine equipment can increase the number of filling heads as needed while filling, speed cleaning, fast adjustment, and stepless speed adjustment of the cylinder operation,

It is used to fill different specifications and different liquids. The filling volume can be adjusted according to the needs, or it can be adjusted by an engineer. It can save a variety of parameters and switch to start use.

Each filling cylinder can be adjusted individually, with high filling accuracy and good consistency.

Filling machines are controlled by PLC. They have novel design, beautiful appearance, stable and reliable performance, high filling accuracy, strong adaptability, simple operation, and convenient maintenance. Some devices can also be used for high temperature filling after special treatment. , And this filling machine not only shines in the cosmetics, food, and condiment industries, but also has many applications in other industries. If the filling machine is to develop in the mature packaging machinery industry in my country for a long time, companies need to make reasonable use of the market. Relations, open up new development models, and open up new markets. Only in this way will it be better.

Determine the product to be filled by your own automatic filling machine. First, determine the material to be filled. Some manufacturers have multiple products. When choosing an automatic filling machine, they want one filling machine to fill them. All varieties, but in fact, the filling effect of the dedicated machine is better than that of the compatible machine. As one of the reference conditions, the customer can coordinate with the manufacturer. The choice of the filling machine for different filling ranges depends on the filling range. If the products with a large gap in the filling range are filled with equipment as much as possible, with high cost performance, the quality of domestically produced filling machines has been greatly improved and can keep pace with imported machines.

If you are interested in our machine , Please feel free contact me.

My name is Alma . My contact information is attached below.

WhatsApp:+8613566223503 Email:[email protected] Wechat: +8613566223503