Now the filling machine is used in the production process by many industry manufacturers, so what should customers pay attention to when mining the filling machine equipment?

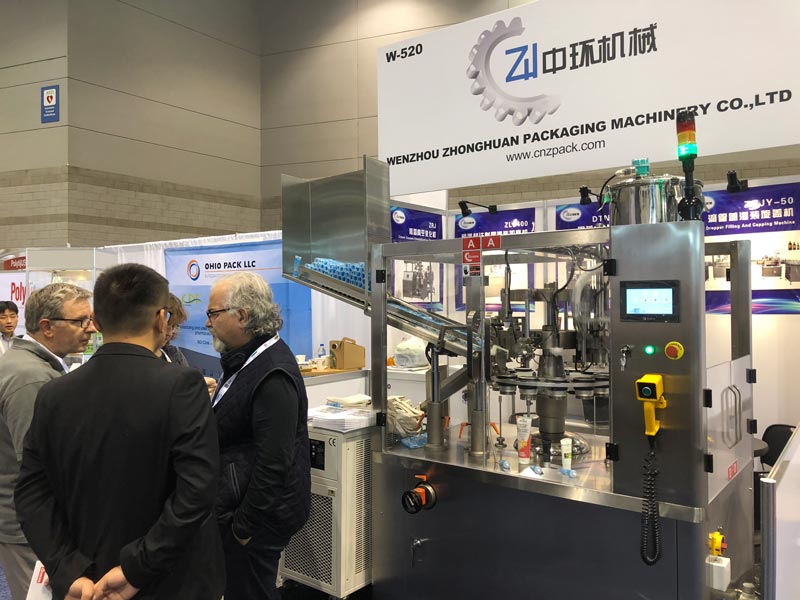

The following suggestions of Zhonghuan Intelligent Machinery can provide you with a reference for purchasing filling machine equipment.

1. Choose equipment manufacturers with reliable quality

At present, there are two options for this kind of equipment on the market: imported and domestically produced. Generally, imported equipment has better performance, but the price is much higher than that of domestically produced equipment, but it cannot provide long-term service due to service problems.

With the continuous improvement of domestic equipment suppliers, the quality of automatic filling machine equipment of some domestic suppliers has reached or exceeded the level of imported equipment. Therefore, users should not blindly believe in imported equipment. Comprehensive consideration of many factors to determine the direction of purchase. Wenzhou Zhonghuan Intelligent Machinery Co., Ltd. is trustworthy.

Second, the selection of filling equipment components

The performance of filling equipment is usually guaranteed by the performance of components, so users should not only pay attention to the overall performance of the equipment when purchasing equipment, but also have an in-depth understanding of the internal components of the equipment, and especially carefully analyze the components of key parts. Whether the performance of the device can really achieve the equipment performance indicators advertised by the supplier. Such as: the reliability of the PLC performance of the control element in the equipment center, whether the control valve meets the sterility requirements and the wear resistance of key structural parts, etc.

Three, the operating speed of the filling machine

The faster the filling equipment runs, the greater the capacity and the lower the cost per unit of output.

Fourth, consider whether the filling machine can be used for multiple purposes

Many manufacturers will choose to produce products with different packaging specifications and materials. In this case, the compatibility of the equipment is very important. The investment in purchasing multiple equipment is too large, but purchasing a filling equipment that can be used for multiple purposes can reduce the investment cost of the equipment.

Five, the installation requirements of the filling equipment and the connection with other equipment

When selecting filling equipment, the user should consider the actual situation of the factory’s factory to ensure that there is enough space for installation. Emulsion filling machine can generally be used in conjunction with other supporting equipment to form a filling machine production line. For example, the connection between equipment and other equipment should also have fully automated production.

Six, pay attention to after-sales service

The failure rate, downtime rate and timeliness of maintenance of filling equipment directly affect the market supply, reputation, manufacturing cost and economic benefits of the company. Therefore, users should choose manufacturers with good after-sales service when purchasing filling equipment.

If you are interested in our machine , Please feel free contact me .

My name is Alma . My contact information is attached below.

WhatsApp:+8613566223503 Email:[email protected] Wechat: +8613566223503